ARO Welding Technologies

Global Leaders. Strategic Alliances.

We collaborate with leading global technology providers to deliver advanced industrial and engineering solutions across the GCC, ensuring innovation, reliability, and industry leadership. Since its founding in Paris in 1949 by Albert Roland, ARO has expanded worldwide with milestones including subsidiaries in Germany, China, Brazil, and the UK, pioneering welding innovations, earning ISO 9001, and achieving global recognition with projects like Servoline and 3G robot guns. Celebrating 75 years of excellence in 2024.

Quality Without Compromise

ARO Welding Technologies

ARO Welding Technologies SAS is a world-renowned pioneer in resistance welding technology, trusted by automotive and manufacturing industries for over 70 years. Specializing in robotic, manual, and stationary welding systems, ARO delivers innovative solutions tailored to global production demands.

Whether it’s spot, projection, seam, or butt welding, ARO ensures high-performance and long-lasting results across the full range of resistance welding applications.

Product Range

Manual Weld Guns

Servoline Manual Welding

A fully plug-and-play manual welding station with servo technology — delivering precision, zero compressed air use, and unmatched operator safety.

Key Highlights

- Plug & Weld: Pre-set system for fast startup

- Adaptive Welding: High weld quality & force control

- Low Maintenance: Up to 7.5M cycles or 6 years

- Operator Friendly: Compact, silent, ergonomic design

- Eco-Friendly: Low noise, no aerosol emissions

Ergoline Manual Welding

Flexible, ergonomic manual welding guns designed for safety, adaptability, and reduced operational costs.

Key Highlights

- Modular Design: Easily adapts to diverse workstation needs

- Ergonomic Options: Customizable for user comfort and efficiency

- Fewer Components: Simplified circuits and design reduce downtime

- Easy Maintenance: Quick access to wear parts via removable cover

- Increased Productivity: Intuitive use reduces operator fatigue

Aluminium Resistance Spot Welding

Key Highlights

- Suitable for 5xxx & 6xxx aluminium alloys

- Applied to sheets, castings, HPDC, and extrusions

- Essential in BIW assemblies and EV battery casings

- Requires high welding current due to conductivity

- Very short welding times (60–250 ms)

- Force profiling ensures consistent weld quality

State of the Art detailed in clear Welding Guidelines

Our detailed welding guidelines are designed to support projects from the earliest stages. They provide comprehensive instructions on implementing RSW into part design, defining robust weld parameters, and ensuring consistent strength. These guidelines also specify equipment requirements and adapt to special configurations when needed.

Key Highlights

- Early-stage project support with precise welding standards

- Defines parameters: welding current, force profiles, and weld strength

- Covers equipment type, size, and application needs

- Custom solutions for varied part thicknesses and adhesive use

- Expert lab trials and technical support available

Robotic Weld Guns

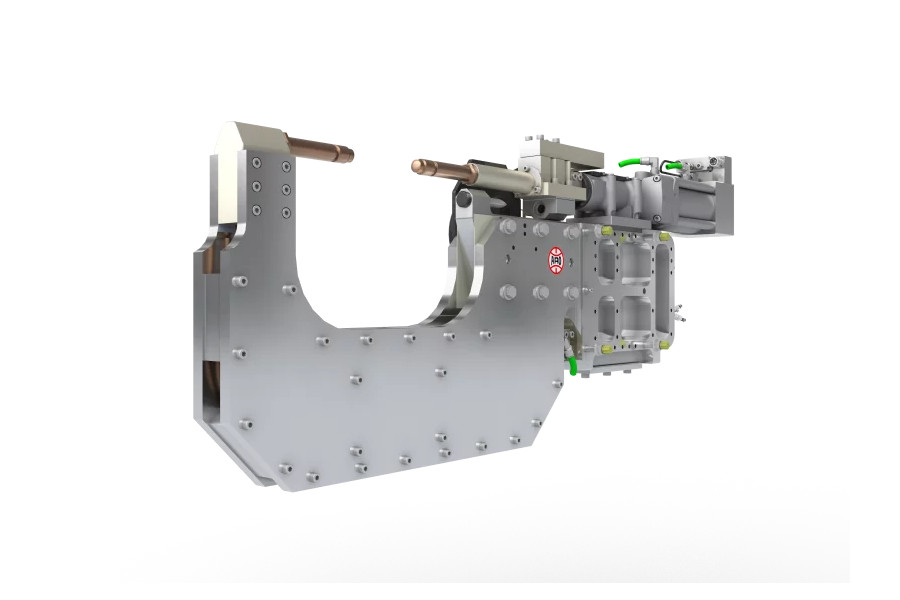

3G Modular Robotic Weld Guns

A game-changing modular robotic welding system designed to reduce costs, simplify maintenance, and boost flexibility — with up to 60% fewer parts than conventional guns.

Key Highlights

- Modular System: 4 gun variants built from 9 shared + 7 specific modules

- Quick Maintenance: Only 3 tools needed; MTTR < 10 minutes

- Global Compatibility: Standardized for worldwide deployment

- Lower Costs: Fewer spare parts, easier assembly, fast delivery

- Plug & Play Arms: Swap between C/X types or copper/aluminum with no rework

- 3G Light Option: For lightweight, low-payload robotic applications

HD Robotic Weld Guns

A long-standing industry favorite for high-force, high-current robotic welding. Built for durability, flexibility, and global integration in demanding environments.

Key Highlights

- High Power Output: Up to 65kA welding current & 2000daN force

- Flexible Application: Spot welding (steel, aluminum) & projection welding (fasteners)

- Stiff & Stable: Rigid gun body minimizes deflection and tip slippage

- Tool Changer Compatible: Easy integration with automation lines

- Fast Assembly: Simplified structure, reduced MTTR

- Shared Components: Parts compatibility with 3G guns reduces inventory costs

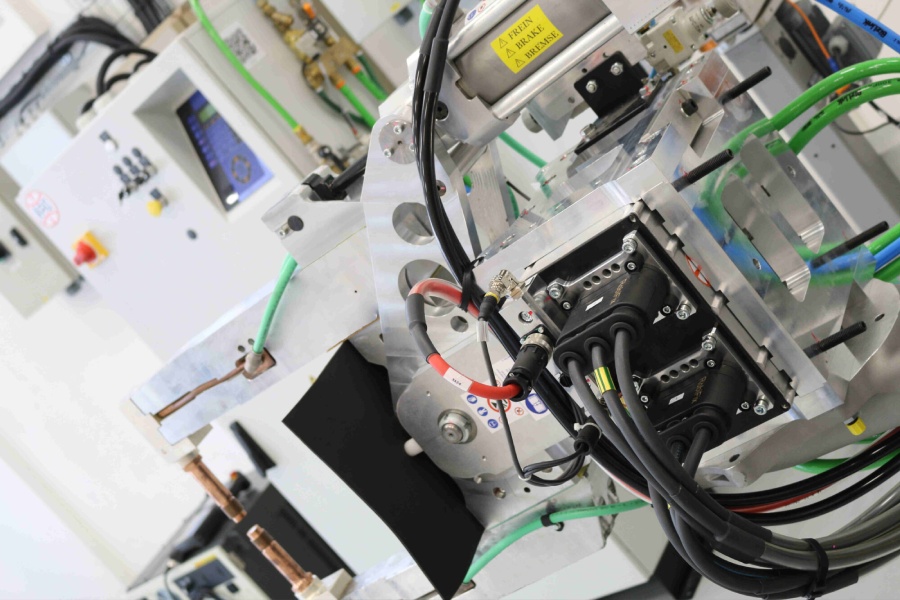

Combining Weld Gun and Controller

Our integrated weld gun and controller solutions deliver competitive workstations designed for aluminium materials from thin to thick. With servo-driven guns, force sensors, and centralized control, these systems guarantee reliability, precision, and seamless compatibility with robotic operations.

Key Highlights

- Handles thin to thick aluminium material combinations

- Stiff servo-driven weld guns with force sensor and brake

- iBox controller manages force profiles and welding parameters

- Centralized data management for reliability and performance

- Fully compatible with robotic systems, including F-Package, dresser, and caps changer

Controls & Software

iBox Controller

Key Highlights

- Universal Compatibility: Works with any 6- or 7-axis robot, no axis drive required

- Advanced Force Control: Synchronized force profiles for high weld quality, ideal for aluminum

- Smart Calibration: Auto detection of electrode wear, geometry, indentation & expansion

- Plug & Play Setup: Pre-wired and calibrated, ready for immediate operation

- Robust Monitoring: Tracks duty cycles of gun actuator, transformer & diodes

- High Accuracy: Electrode position and force control for consistent weld quality

MFDC Controllers

Key Highlights

- Compatible with major fieldbuses: Ethernet IP, Profinet IO, Profibus DP, and more

- Manages up to 256 welding schedules

- Compact, safety-focused design with adaptive self-learning

- Automatic compensation for material differences, tip wear, gaps & adhesives

- Steel Quality Assurance (SQA): Real-time weld quality scoring and detection

- Energy-efficient MFDC vs. AC: 20% lower electrical consumption

AC Controllers

Reliable and proven AC control systems from ARO, ideal for manual and robotic welding applications with flexible power ranges and wide fieldbus compatibility.

Key Highlights

- Supports up to 128 welding schedules

- Fieldbus-ready: Ethernet IP, Profinet IO, Profibus DP, Interbus-S, DeviceNet

- Modular, compact cabinet design with media panel support

- Wide power range from 18 kVA to 550 kVA

- Works across manual guns, robotic guns, and machines

- Trusted 2X16 III and AR01NG systems used globally

Software

A complete suite of industrial software tools for programming, supervision, and optimization of ARO welding controllers across factory networks.

Key Highlights

- ARONET 6 – Real-time WCC supervision with centralized control

- ARONET VIEWER 6 – Analyze and open ARONET restore points

- ARODMS 6 – Offline programming of weld control cabinets

- Recovery 6 – Easy setup restoration and data backup

- Windows 8–11 (64-bit); Intel i3+; 100GB HDD; min 768px screen height

Stationary Weld Machines

Omega series

Key Highlights

- Fully modular design for customized bench setups

- Available in both Pneumatic and Servo models

- MFDC & AC transformer options (up to 20kA current)

- Force range: 30–120 daN / Max force: 1.2 kN

- Servo Omega: Water-cooled, maintenance-free up to 5 million cycles

- Reduced downtime & energy costs (no compressed air in servo version)

M series

A robust and space-efficient range of stationary spot and projection welding machines, built to meet precision, durability, and productivity demands in industrial applications.

Key Highlights

- Optimized for Spot & Projection Welding

- Compact and robust construction for long-term reliability

- Standard-equipped with customizable options

- Pneumatic actuation across all models

- Compatible with ARO control systems and power cabinets

P series

Key Highlights

- Available in AC and MFDC configurations

- Servo actuator with embedded force sensor for precise control

- Compatible with iBox controller for full weld process management

- Supports pneumatic or servo actuation with part thickness detection

- Fieldbus-ready for easy PLC or robot communication

- Seam welding-ready with single/double servo-driven wheel options

MOS series

Key Highlights

- Aerospace-qualified (MOS II AERO) – ideal for aluminum, titanium, and stainless steel

- Servo & pneumatic actuator options across spot, projection & seam welding

- Up to 100kA welding current and 54kN welding force

- Seam welding configurations with servo-driven wheels and customizable layout

- iBox-driven with full force profile and weld data traceability

- Supports MFDC and AC technologies

CD Capacitor discharge Welding Machines

ARO’s CD Series welding machines deliver high-current projection welding using capacitor discharge technology — ideal for applications requiring speed, efficiency, and low energy consumption.

Key Highlights

- Capacitor discharge delivers ultra-fast welding pulses

- Generates high welding currents with low power input

- Ideal for projection welding applications

- Available in Servo-actuated compact design

- Includes intuitive touchscreen HMI for easy control

- Customizable tooling & safety systems

Interested in ARO’s welding solutions?

Contact us to explore how we can bring ARO’s technology to your operations.