Kyokutoh

Trusted by Global Car Manufacturers

About Kyokutoh

KYOKUTOH is a leading Japanese specialist in intelligent welding applications, partnering with major car manufacturers worldwide for reliable, automated electrode tip dressing and changing. With nearly seven decades of experience, we deliver customizable and efficient solutions tailored to modern car body production needs, ensuring seamless adaptation to evolving manufacturing demands.

Our proven standard tip dresser and changer systems can be expanded with custom components, offering flexibility and long-term value. Through on-site consultation and continuous collaboration with our partners, KYOKUTOH remains committed to advancing automated welding technology in line with the latest automotive industry trends.

Product Range

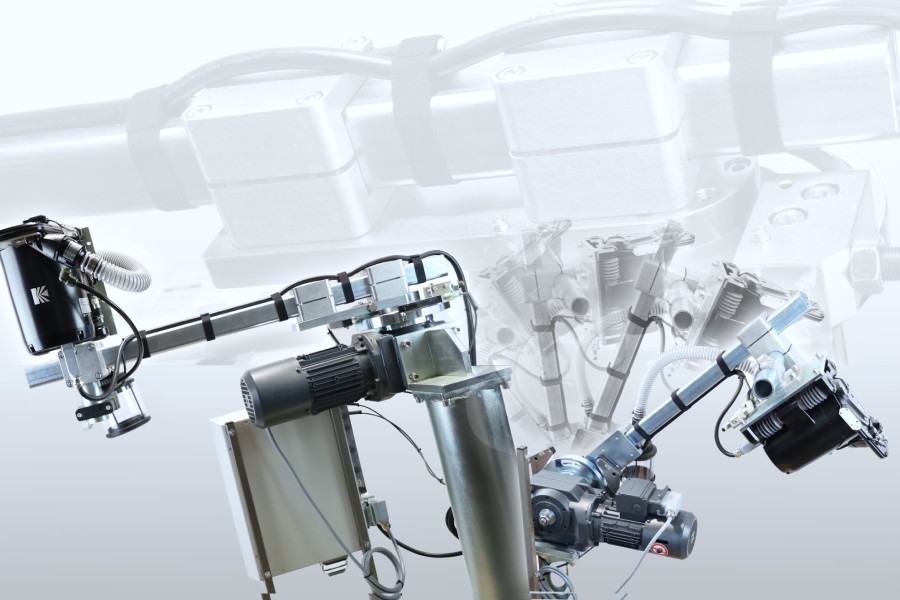

Tip Dressers

Tip Dresser Sets

Reliable and efficient electrode tip dressing systems designed for automated production — ensuring consistent weld quality and reduced downtime in demanding environments.

Categories

- KE CDK-BAYO SET

- KE CDK-R SET

- KE CDK-SG SET

- KE CDK-SSG SET

Key Highlights

- Automated dressing for consistent electrode shape

- Ideal for high-throughput automotive manufacturing

- Enhances process reliability and weld quality

- Designed for continuous industrial use

- Minimizes downtime and manual intervention

- Compatible with various electrode types and gun configurations

Swing Arm Sets

Key Highlights

- Available in horizontal (SEH) and vertical (SEV) models

- Swivel range: 60° to 190°, optional 360° base adjustment

- Plug & Play system — no programming required

- Double-sensor system enables smooth, vibration-free approach

- Frequency-controlled movement for fast positioning

- Integrated chip vacuum system for clean operation

- Built-in motor protection switch for operator safety

- Spring-loaded for synchronized electrode dressing

Manual Tip Dressers

Reliable and ergonomic hand-held tip dressers designed for manual maintenance of electrode tips — ideal for low-volume operations or backup support in welding environments.

Categories

- NEW-ETD

- WPD Hand Dresser

Key Highlights

- Hand-operated for quick and simple electrode maintenance

- Designed for mobility and ease of use

- Suitable for workshops, repair areas, or low-duty cycles

- Ensures consistent dressing quality between automated cycles

- Complements automated tip dresser systems

Options / Accessories

Categories

- Chip Vacuum System CVC5

- Cap Tip Sensor FIXA2

- Teachingholder KTW-EUR-TEACH01

Key Highlights

- Mounting brackets & adjustment bases for flexible positioning

- Custom tool holders and cutters for various electrode types

- Chip collection & extraction enhancements

- Swivel bases, adjustment plates & extension arms

- Frequency converters & control unit accessories

- Sensor kits & safety integration components

- Compatible with CDK-BAYO, KE SEH/SEV, manual dressers

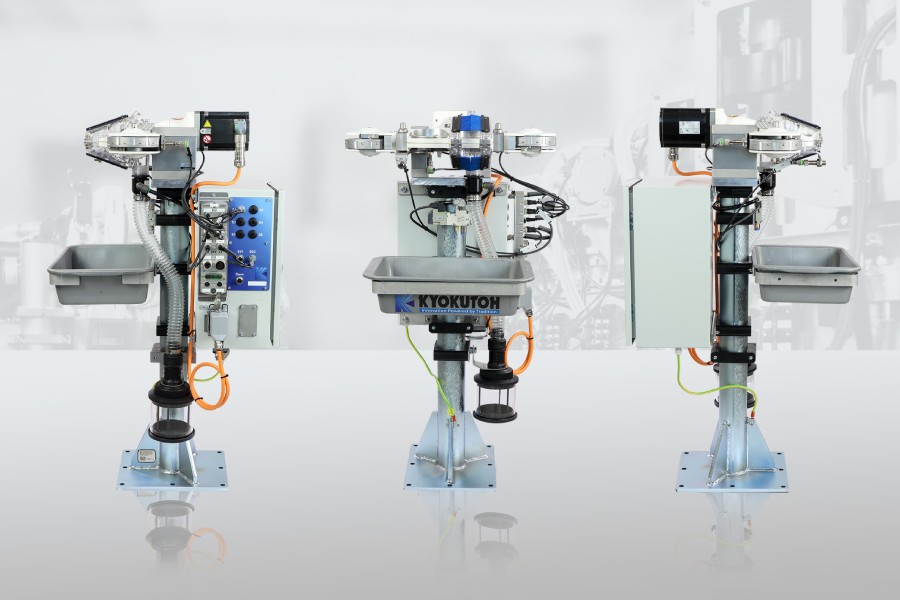

Tip Changers

Tip Changer Sets

Categories

- KE KIKK-ELX SET

- KE KIKK-SGX SET

Key Highlights

- Fully integrated Plug & Play solution

- Fast, reliable electrode tip exchange

- High durability and long service life

- Minimal maintenance requirements

- Ensures process continuity & reduced downtime

- Designed for automated welding cells & robotic systems

Options / Accessories

Categories

- Electrode Tip Magazines

- Teaching Aid TT-ATC

- Forksensor FSK35

- Manual Tip Changer TRYZ

- Water Draining System CWDS-01

Key Highlights

- Mounting adapters for various robot types & welding guns

- Customizable changer holders, trays

- Sensor kits & safety components

- Replacement tool inserts and tip holders

- Integration accessories for Plug & Play compatibility

- Maintenance-friendly design for quick upgrades or changes

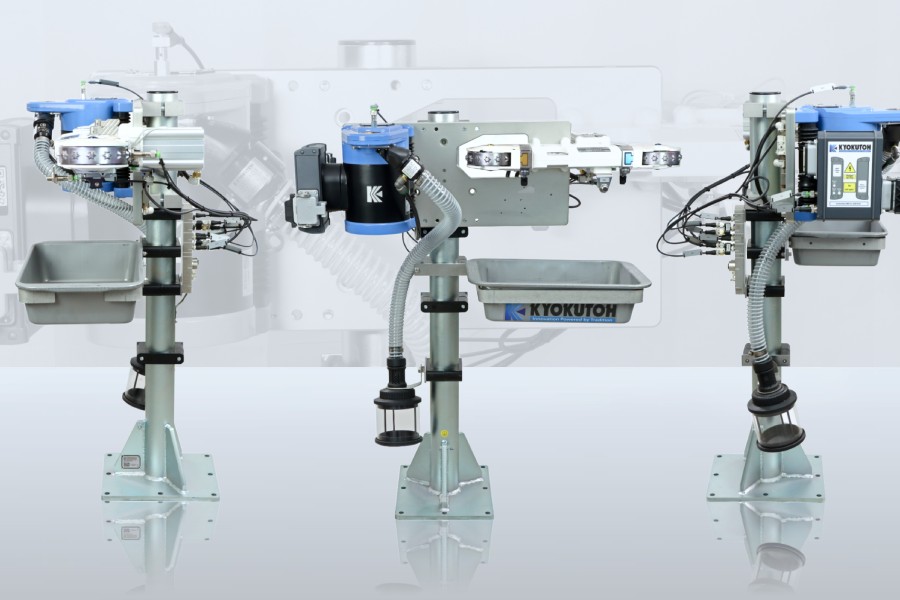

Tip Dresser/Changer Combinations

KE CDK-BAYO KIKK-ELX SET

Key Highlights

- Combines CDK-BAYO (tip dresser) & KIKK-ELX (tip changer) in one system

- All-in-one automation for tip dressing and replacement

- Durable construction for long service life in any working position

- Pneumatic changer system delivers high force for secure tip loosening

- Ideal for aluminum and high-load welding applications

- Integrated spring assembly ensures synchronized dressing

- Built-in control box for Plug & Play installation

- Powerful chip extraction system and motor protection switch included

KE DH-SVR2 X SET

Kyokutoh’s next-generation compact unit combining tip dressing and changing with intelligent control features — designed for high-performance robotic automation and adaptive process optimization.

Key Highlights

- Integrated tip dresser + tip changer in one compact unit

- Optional servo motor drive for adaptive control via robot controller

- Collects and monitors process data (motor current, speed, direction)

- Frequency converter enables variable speed settings

- Ideal for high-speed, process-reliable production

- Long service life due to premium materials

- Plug & Play ready with flexible installation options

Milling Tools

Milling Tools for standard applications

Kyokutoh’s high-performance cutter holders and blades deliver long tool life and consistent tip dressing — even in tough production environments. Engineered for compatibility and fast changeover.

Key Highlights

- Wide selection of cutter holders and blades for various materials & tip types

- Standard models: KTW / KTWH series

- Bayonet-mount cutter holders for quick tool changes

- Optimized chip openings for clean, precise shape dressing

- Durable cutting edges ensure long service life under demanding use

- Compatible with most standard dressing machines

- Standard and custom solutions available

- Many models in stock or available for fast delivery

Milling Tools for special applications

Engineered for advanced and custom welding requirements, Kyokutoh’s special milling tools offer unmatched precision, longevity, and performance — including solutions for ultra-high-strength steels and aluminum spot welding.

Key Highlights

- Over 3,000 specialty cutter types for tailored dressing

- HT cutters for non-galvanized, galvanized steel & Usibor

- Tools for C/X guns, servo-pneumatic or electric systems

- Raised cutters for narrow welding guns

- Compatible with variable clamp forces, tip geometries & dress intervals

- Optional screwed-in and high-release chip opening designs

- Specialized tools to minimize electrode wear and reduce redress

Interested in KYOKUTOH Europe GmbH?

Contact us to explore how we can bring KYOKUTOH Europe GmbH to your operations.