Manual Welding Solutions

In addition to the Ergoline range of pneumatic manual welding solution, ARO innovates by proposing SERVO manual solutions. The Servo technology brings to the manual welding operations all its strong benefits – high performances, cost efficiency, and highest reliability.

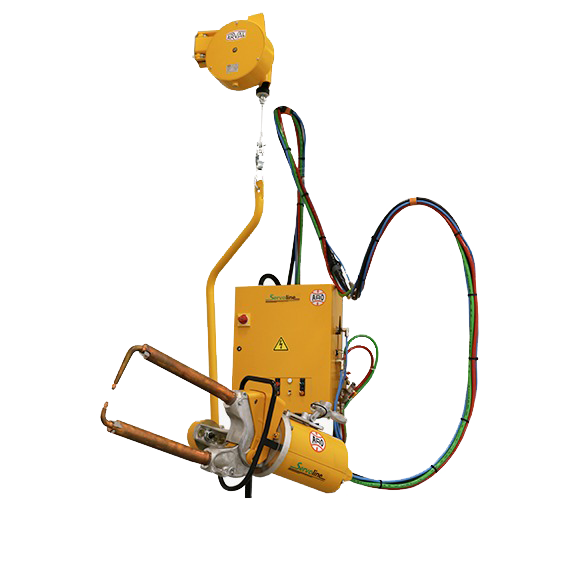

Ergoline Manual Welding Station

In manual welding applications where safety, ergonomics and reliability are paramount, ARO offers its Ergoline range of modular welding guns and its ensuing models, Ergolean.

With thousands of these stations already in operation worldwide Ergoline has more than proved itself with clients in the automotive sector and other industries. Its easy to handle design allied to an excellent power to weight ratio ensures that this market leading range meets all manual welding applications.

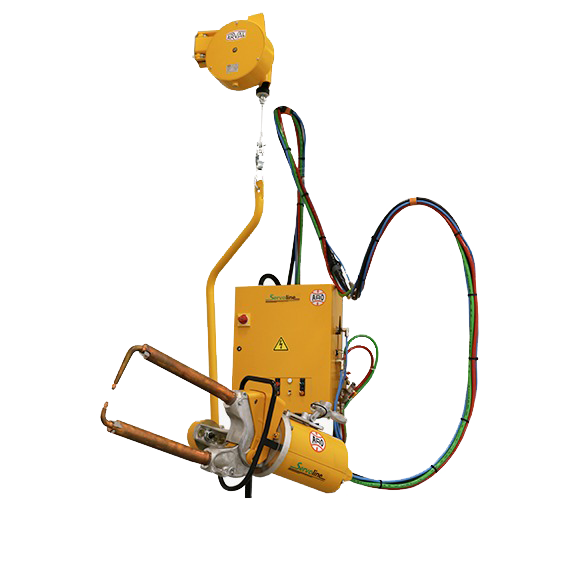

Servoline : servo manual welding station

ARO innovates by proposing SERVO manual solutions . The Servo technology brings to the manual welding operations all its strong benefits – high performances, cost efficiency, and highest reliability. – henceforth recognized by the automotive industry using almost 100% of sevo welding guns for robotics.

Immediate savings and simplicity : the use of the servo technology eliminates the need for compressed air in manual welding.

| TECHNOLOGY | SERVO – MFDC | PNEUMATIC – MFDC |

|---|---|---|

| Type of gun | Servoline | Pneumatic Gun |

| Compressed Air | ✓ | |

| Reduced size and weight | ✓ | |

| Vibration free | ✓ | |

| Noise free | ✓ | |

| Programmable openings | ✓ | |

| Type of Controller | ASW (Adaptive Servo Weld) 260 | MFDC controller |

| AW Auto-Adaptive | ✓ | |

| Wireless Programming | ✓ |

Robotic Welding Solutions

Integrated transformer welding guns have revolutionised robotic assembly lines; tens of thousands of ARO robotic welding guns have equipped the large automotive manufacturing plants for many decades.

Reliable and robust, ARO robotic welding guns are capable of welding at a higher rate of production. Compact and modular, they adapt perfectly to the needs of each application equipped with High performance transformers in AC or MFDC; Non lubricated pneumatic or electric actuators allowing a welding force up to 1200daN electrodes; Standard or special arms according to usage.

Combined with an ARO controller, the robot gun can attain a very high welding current.

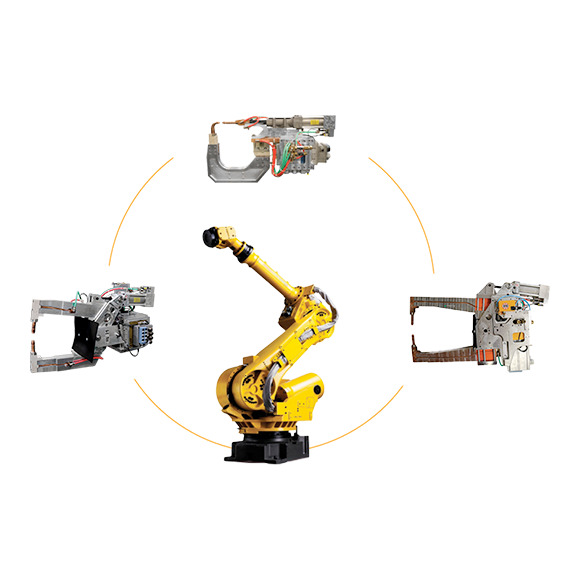

3G Modular Robotic Welding Guns

The manufacturing industry is under constant demand to improve efficiency and reduce costs. ARO has risen to the challenge and produced the first modular system, the 3G robotic welding gun. The revolutionary 3G modular system allows four gun variations to be created from 9 shared modules, 7 specific modules and 2 plug and play arms.

Using ARO’s unequalled modular and servo gun expertise, the family of 3G guns has up to 60% fewer parts than conventional gun designs and there is a high degree of component commonality between all of the 3G gun types.

Stationary Welding Solutions

ARO provides solutions to meet spot, seam, butt and projection welding applications. All requirements for these four types of welding are easily met by ARO’s wide range of options in these world class stationary welding machines.

ARO's Heavy Duty Welding Guns

This HD Range of robotic guns has been a success with customers for many decades and is still a model of reliability and robustness. The machine is available in several models with a perfect power to weight ratio, which can be adapted to any technical specification to respond to all requested applications.

ARO has a range of 3 different gun Bodies to cover full range of applications. This allow reduced investment in spare guns and due to standardisation of parts, reduced costs for spares.

| Ergoline Type | RCF | RWG | RHG |

|---|---|---|---|

| Design Current | 55 kA | 55 kA | 65 kA |

| Design Force | max 1200 daN | max 1200 daN | max 1200 daN |

| Cooling | Water | Water | Water |

| Compatibility | Any Robot | Any Robot | Any Robot |

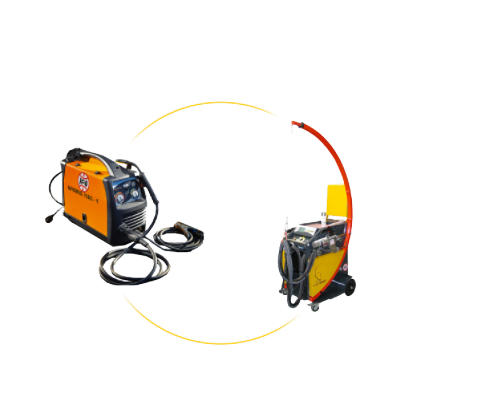

Spot and Mig Mobile Welding

The ARO mobile welding product range was developed with the automotive motor body repair (MBR) market firmly in mind. Since the company’s inception, over a quarter of a million spot welders have been supplied by ARO to the automotive industry. Today, ARO continues to innovate, providing solutions for higher production through the provision of the multi-function equipment and lower operating costs demanded by today’s automotive repair market.

Combining Welding Gun and Controller

Competitive complete work stations, covering part combinations ranges from thin to thick Steel materials. Full compatibility, clear and documented behaviour. High reliability & guaranteed performance and compatible with any robot.

| Welding Gun | 3G / HD | 3G / HD |

|---|---|---|

| Welding Controller | iBox 800 / 1200 / 2400 | MFDC 800 / 1200 / 2400 |

| Aluminium welding | ✓ | ✓ |

| Process disturbances compliant | ✓ | |

| Welding through Adhesive | ✓ | |

| Field Bus communication | ✓ | ✓ |

| Current monitoring | ✓ | ✓ |

| Current control | ✓ | ✓ |

| Force monitoring | ✓ | |

| Force Control | ✓ | |

| Force Profile | ✓ | |

| Position during welding | ✓ |

Omega

ARO have devised and designed a new series of modular bench mounted machines that offer a wide range of possible assembly combinations.

More Details

| Ergoline Type | RCF | RWG | RHG |

|---|---|---|---|

| Design Current | 55 kA | 55 kA | 65 kA |

| Design Force | max 1200 daN | max 1200 daN | max 1200 daN |

| Cooling | Water | Water | Water |

| Compatibility | Any Robot | Any Robot | Any Robot |

N Series

Flexible design ,High performance and durability ,Low energy consumption ,Designed for welding quality

More Details

| TYPE | N |

|---|---|

| Application | Spot Welding |

| Technology | AC |

| Actuator | Pneumatic |

| Max. force | 60 – 200 daN |

| Max. Current | 15 kA |

M Series

Flexible design ,High performance and durability ,Low energy consumption ,Designed for welding quality

More Details

| TYPE | MA | MB | MC |

|---|---|---|---|

| Application | Spot Welding | Projection Welding | Spot Welding |

| Technology | MDC / AC | MDC / AC | MDC / AC |

| Actuator | Pneumatic | Pneumatic | Pneumatic |

| Max. force | 730 daN | 740daN | 970 daN |

| Max. Current | 45kA (AC) – 20kA (DC) | 45kA (AC) – 20kA (DC) | 50kA (AC) – 20kA (DC) |

MOS Series 100kA DC

Flexible design , High performance and durability , Low energy consumption , Designed for welding quality ,Pneumatic or Servo technology

P Series

ARO, worldwide leader in the area of resistance welding has designed this range of medium-power machines to cover the 4 families of resistance welding: projection, spot, seam and butt welding.

More Details

| TYPE | PA | PB | PE | PF |

|---|---|---|---|---|

| Application | Spot Welding | Projection Welding | Seam Welding | Butt Welding |

| Technology | MFDC / AC | MFDC / AC | MFDC / AC | AC |

| Actuator | Servo / Pneumatic | Servo / Pneumatic | Pneumatic | Pneumatic |

| Max. force | 740 daN | 1400 daN | 480 daN | 900daN |

| Max. Current | 45 kA | 55kA | 20 kA | 25kA |

MOS Series

Flexible design ,High performance and durability ,Low energy consumption ,Designed for welding quality ,Pneumatic or Servo technology

More Details

| TYPE | MOS II | MOS III AERO | MOS III | ||

|---|---|---|---|---|---|

| Application | Spot / projection welding | Seam | Spot | Spot / projection welding | Seam |

| Technology | MDC / AC | AC | MFDC | MDC / AC | AC |

| Actuator | Servo / Pneumatic | Pneumatic | Servo | Servo / Pneumatic | Pneumatic |

| Max. force | 2000 – 2400 daN | 1000daN | 2000 daN | 2000 – 5400 daN | 1500daN |

| Max. Current | 100kA (AC) -55kA (DC) | 27kA (AC) | 55kA (DC) | 100kA (AC) – 100kA (DC) | 27kA (AC) |

CAPACITOR DISCHARGE

To satisfy market demands, ARO has extended its range of products by supplying capacitor discharge welding machines dedicated mainly to projection welding applications. This technology works by storing energy in capacitors which on discharging, release the current by very fast pulse. It is possible in this way to produce very high welding currents with a very low supply consumption.

More Details

| TYPE | K 12 F3000N | K 18 F3000N | K 18 F4500N |

|---|---|---|---|

| Application | Projection / Spot Welding | Projection / Spot Welding | Projection / Spot Welding |

| Technology | Capacitor Discharge | Capacitor Discharge | Capacitor Discharge |

| Actuator | Servo | Servo | Servo |

| Max. force | 4500 daN | 3000 daN | 4500 daN |

| Welding Current | 120kA | 200 kA | 200 kA |

| Supply | 63 A | 63 A | 63 A |

start your project now

contact us today

info@panirex.com

We reply within 24 hours

Contact Now

P.O. Box 262076

Tel: 009714-8810866

Fax; 009714-8810867

Address

Jafza 7 Building Office F03 Jebel Ali Freezone Dubai UAE

Copyright © 2021. Panirex FZE. Powered by Catnyx Digital Media